BAST Sheet Straightening Machine

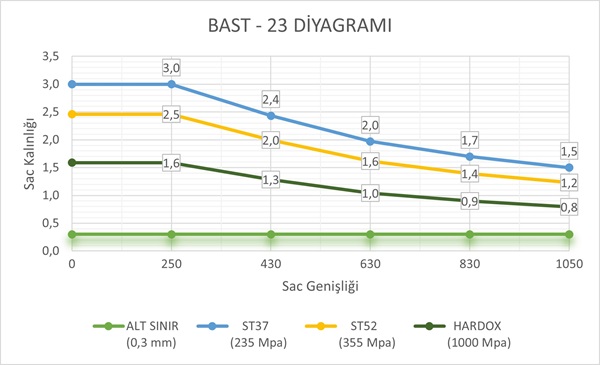

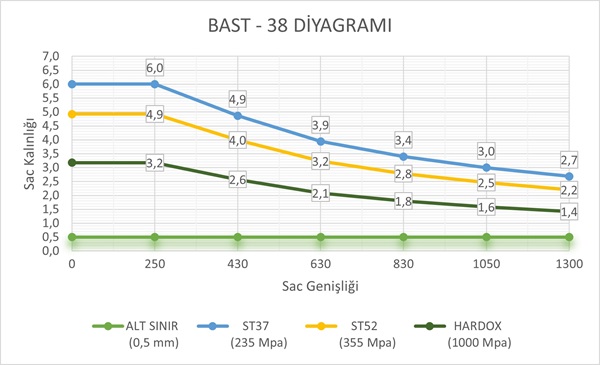

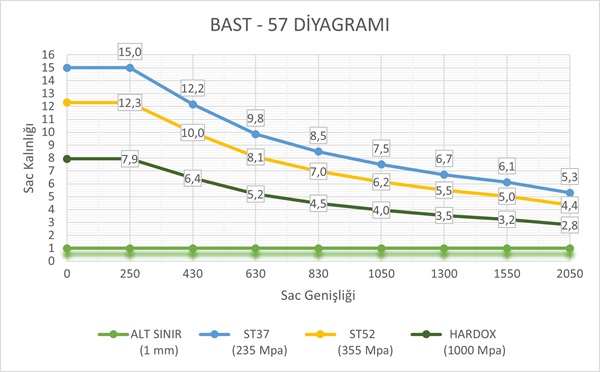

Today, roller leveling technologies are rapidly replacing the old methods in removing the defects that occur in laser metal sheet cutting, flamed cutting or perforated surfaces. The roller straightening machine reduces the internal tension of the sheet metal parts coming from the laser cutting, allowing them to be straightened. Thus, the process quality is increased in production processes such as precision welding, bending and twisting following leveling.

Compared to other straightening processes, roller hair straightening is a fast, economical, short-term, simple process that can be performed with short training in terms of technical personnel. Reversible leveling rollers extend the service life of the roller and minimize wear. It is very practical to take the cassettes out and clean them with a motorized stand.

Equipping the BAST Machine with an overload protection system increases the fatigue strength and service life of the machine. BAST Machine mold cavity settings are supported by sensitive sensors, and the smoothing precision process remains stable. Thanks to the EASYBAST touchscreen, machine settings can be made in sensitive value ranges and the program can be used easily.

For more information about BAST Sheet Metal Straightening Machine, please visit bastmachine.com