Meşe Makine was established in Bursa in 2009 and started new machine designs and productions with high production technology. With its engineering experience, it is trying to produce machines that the production sector needs and to present them to the world market. Between 14 December – 17 December, Bursa Machinery Technologies (BUMATECH) fair was held between the dates, participating in the other hair processing machinery product groups, the new machine BAST Sheet straightening machine was presented to Turkey and the world market. With 30 years of engineering experience, it introduced its machine, which it produced with a special design to eliminate the defects that occur in hair cutting, at the fair.

As MEŞE MAKİNA, we participated in the Metal Processing Technologies, Sheet Metal Processing Technologies and Automation fair held on 14-17 December 2022. It was a pleasure for our company to take part in this fair, which was attended by 378 companies and company representatives and visited by 36,762 people from 67 countries.

We participated in the fair with the BAST Sheet Straightening machine with Utility Model No. 2022/019163. We owe a debt of gratitude to our visitors from Turkey and abroad who showed serious interest in our machine. Our visitors were told that our BAST Sheet Straightening machine performs simple, silent, fast and economical sheet metal straightening. The straightening of waste sheets of various thicknesses that come to our hands after laser cutting was shown practically. It was approved by the leading people of the sector that the BAST Machine performs the sheet metal straightening process perfectly.

Design and manufacturer of the BAST machine Mak. Eng. Mehmet Selim Akkök about the fair: “I sincerely believe that the machine we built will close a serious gap in the sheet metal processing sector. The fact that the BAST machine is a domestic production will provide convenience to our customers in terms of accessibility, budget suitability and service.”

İçindekiler Tablosu

You may be interested in this article. Special Machine Manufacturing and Industrial Automation

Bast Sheet Straightening Machine

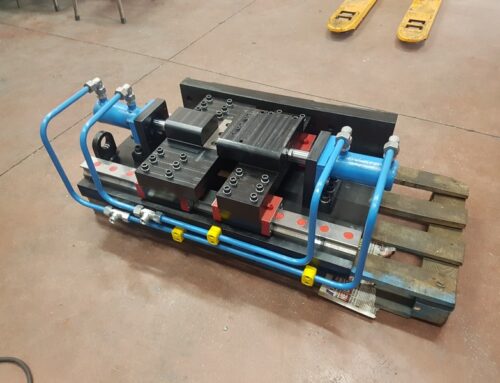

Meşe Makine has carried out R&D studies to improve material quality in sheet metal processing operations. As a result of the R&D studies, it designed the BAST sheet straightening machine. In different areas of the production sector, roller straightening technologies are used to eliminate defects that occur in flame cutting, laser cutting and perforated sheet metal processes. Flattening processes reduce the internal tension in sheet metal parts and increase the quality of the process on the product by flattening.

BUMATECH Fair

BUMATECH fair was held on 14 -17 December 2022 and hundreds of companies participating in this fair introduced their new products. Meşe Makine company prepared a stand to present the BAST machine, which attracted great attention. He states that he has received many orders for the BAST machine, which attracted great interest in the sheet metal straightening and sheet metal processing sectors. Compared to other technologies used in sheet metal straightening processes, BAST enables all processes to be done faster and more economically. With its many features, it enables the production sectors to perform their operations with simple methods and to have a durable, long-lasting machine. Meşe Makine has already started working to present new products at the BUMATECH fair to be held in December 2023.

Bast Machine

BAST is one of the newly designed products of Meşe Makine. It is designed as a roller sheet straightening technology and is an economical, easy and simple-to-use machine that saves time by making fast processing. With this feature, it has attracted great interest from all customers and has received many orders. The rollers that perform the sheet straightening process can be used in both directions. This reduces wear on the rollers and extends the service life of the machine. It is as easy to clean after the process as it is to use. It also provides precise and easy programming of the settings related to the operations to be performed on the touch screen.

Sheet Straightening Processes

It is constantly making new studies to increase product quality and improve business processes in production technologies. Meşe Makine, using its 30 years of engineering experience, presented the BAST machine at the fair, which will enable sheet metal straightening processes to be carried out more efficiently. It presents all the details showing the features of this machine on its website. While promoting the machine at the fair, all the features and process capacities of three different models were demonstrated by technical staff. Instead of the old methods used for sheet metal straightening, it enables the use of roller straightening and new technologies. With the new technology, it eliminates the defects that may arise in sheet metal processing processes, while ensuring that the processes are completed quickly.

Bast Models

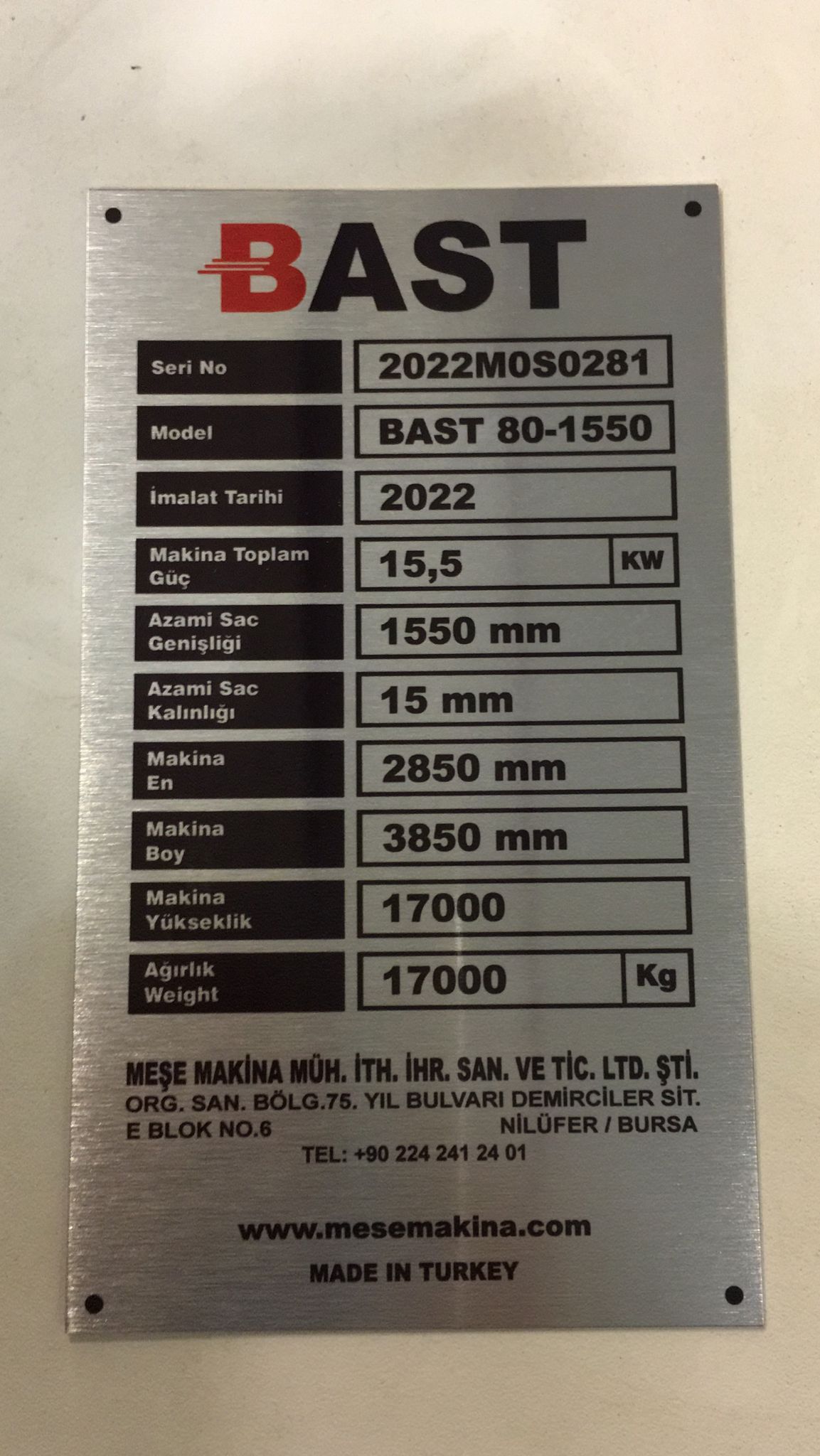

Meşe Makine offers the BAST machine, which was introduced at BUMATECH and received many orders, in three different models. Each model has different machine dimensions and sheet widths that can be processed. All models have features such as touch screen, automatic gap adjustment, standard two-way die, and electromagnetic die adjustment. All detailed information about the BAST 57-80, BAST 57-1250, BAST 57-1550 models is available on the website and in the product catalog. It performs flattening operations for sheet thicknesses of 1-15 by determining precise value ranges on its bidirectional roller machine.

Machine Manufacturing

Meşe Makine introduces its new technologies to the Turkish and world market with easy methods thanks to the fair events. By presenting the BAST technology to the customer masses at the fair, it enabled the production sectors to benefit from this technology and to create orders at affordable prices. It works continuously with all its teams for machine production and ensures that new technologies are produced cost-effectively. BAST sheet metal straightening machine is manufactured to be resistant to abrasion and long-lasting with the technology and material properties used.

Bast Usage

It provides short training with its technical staff for the use of the BAST machine, which it introduced at the BUMATECH fair and collected orders for sales. It is a machine that is easy to use and easy to program on the touch screen. Thanks to its precise and automatic adjustment features, it provides ease of use and enables faster and higher quality sheet straightening processes than conventional technologies. Since it has an overload protection system, it reduces the strength to be applied to the machine and increases the service life of the equipment.

Bast Machine Maintenance and Cleaning

On the BAST machine, the straightening rollers can be used in both directions. The fast and easy-to-clean mould structure ensures that all kinds of maintenance can be done easily. The flattening cassettes can be placed on the motorized stand and all kinds of maintenance and cleaning can be done. While promoting the product at the fair, the company also informed its customers with its technical teams about its processing capacity, usage, maintenance and cleaning. The BAST machine started to take its place in the world market in a short time.

Leave A Comment