Metal sheet leveling machines play a crucial role in various industries that rely on the precise flattening and shaping of metal sheets. Whether you’re in the automotive, aerospace, or construction industry, choosing the right metal sheet leveling machine is essential for achieving optimum performance. With numerous options available in the market, it’s important to understand the key features that differentiate an exceptional machine from an average one. In this article, we will explore the top features to look for in a metal sheet leveling machine to ensure superior performance and quality results.

İçindekiler Tablosu

1. Introduction

Metal sheet leveling machines, also known as precision levelers, are used to eliminate imperfections and distortions in metal sheets, resulting in flat and uniformly leveled surfaces. These machines are designed to handle various types of materials, including steel, aluminum, and stainless steel, and are vital for industries that require accurate and consistent metal sheet processing.

2. Importance of Metal Sheet Leveling Machines

Metal sheet leveling machines are critical for achieving high-quality products and ensuring the efficiency of downstream processes. By removing material stresses and deformations, these machines enable manufacturers to work with flat and stable sheets, minimizing production errors and enhancing the overall quality of the final products.

3. Accuracy and Precision

One of the primary features to consider when selecting a metal sheet leveling machine is its accuracy and precision. The machine should be capable of delivering consistent leveling results with minimal thickness variations across the entire sheet. Look for a machine that offers advanced leveling algorithms and real-time feedback control systems to ensure precise leveling and minimal material loss.

4. Coil Handling Capabilities

In many applications, metal sheets are processed from coils. Therefore, it’s important to choose a leveling machine that can efficiently handle coiled materials. Look for features such as automatic coil loading and unloading, coil centering mechanisms, and adjustable coil guides. These features not only enhance productivity but also minimize downtime during coil changes.

5. Material Thickness Range

Different industries require the processing of metal sheets with varying thicknesses. A versatile metal sheet leveling machine should be capable of handling a wide range of material thicknesses without compromising its performance. Ensure that the machine you choose can effectively process both thin and thick sheets, allowing for maximum flexibility in your operations.

6. Speed and Productivity

Efficiency and productivity are key factors in today’s competitive manufacturing landscape. Look for a metal sheet leveling machine that offers high processing speeds without sacrificing accuracy. Consider features like multi-roll leveling systems, fast material feeding mechanisms, and automated controls to achieve maximum productivity and shorten production cycles.

7. Automation and Controls

Modern metal sheet leveling machines are equipped with advanced automation and control systems that simplify operation and increase efficiency. Look for features such as touchscreen interfaces, intuitive software, and programmable leveling parameters. These features not only enhance user experience but also allow for easy customization based on specific material and processing requirements.

8. Durability and Reliability

A metal sheet leveling machine is a significant investment, and it’s crucial to choose a machine that is built to last. Look for a machine constructed from high-quality materials, such as durable steel frames and components. Additionally, consider machines that come with warranties and have a proven track record of reliability in the industry. A reliable machine will minimize downtime and maintenance costs, ensuring uninterrupted production.

9. Maintenance and Service

Regular maintenance is essential to keep your metal sheet leveling machine in optimal condition. Look for machines that offer easy access to components for cleaning, lubrication, and inspection. Additionally, consider machines that come with comprehensive service and support packages, including preventive maintenance schedules and readily available spare parts. Prompt and efficient service ensures that your machine stays operational and minimizes any production disruptions.

10. Safety Features

Safety should always be a top priority in any industrial setting. When selecting a metal sheet leveling machine, consider the safety features it offers. Look for features such as emergency stop buttons, safety interlocks, and protective guards. Machines equipped with advanced safety systems, such as laser scanners or light curtains, provide an extra layer of protection for operators.

11. Cost and Return on Investment

While the initial cost of a metal sheet leveling machine is an important consideration, it should be viewed in the context of the machine’s long-term value and return on investment (ROI). Evaluate the machine based on its overall performance, durability, and productivity-enhancing features. A machine that offers superior quality and efficiency may justify a higher initial investment by delivering higher productivity, reduced material waste, and improved product quality over time.

12. Integration with Existing Systems

In many manufacturing facilities, metal sheet leveling machines are part of a larger production line. It’s essential to choose a machine that seamlessly integrates with your existing systems and processes. Consider compatibility with other equipment, such as feeders, cut-to-length machines, or downstream automation systems. Smooth integration minimizes bottlenecks, optimizes workflow, and ensures efficient material flow throughout the production line.

13. Customization Options

Every manufacturing operation has unique requirements and specifications. Look for a metal sheet leveling machine that offers customization options to meet your specific needs. Whether it’s adjusting leveling parameters, incorporating additional sensors, or integrating specialized software, customization ensures that the machine aligns perfectly with your production goals and processes.

14. Customer Support and Training

Choosing a reputable manufacturer that provides excellent customer support and training is vital. Ensure that the manufacturer offers comprehensive training programs for machine operation, maintenance, and troubleshooting. Additionally, consider the availability of technical support and the manufacturer’s reputation for responsiveness and reliability. Strong customer support and training ensure that you can make the most of your metal sheet leveling machine and address any issues promptly.

15. Conclusion

When it comes to selecting a metal sheet leveling machine for optimum performance, there are several key features to consider. From accuracy and precision to durability, automation, and customization options, each feature plays a crucial role in achieving high-quality results and maximizing productivity. By carefully evaluating these features and aligning them with your specific production requirements, you can make an informed decision that ensures the long-term success of your operations.

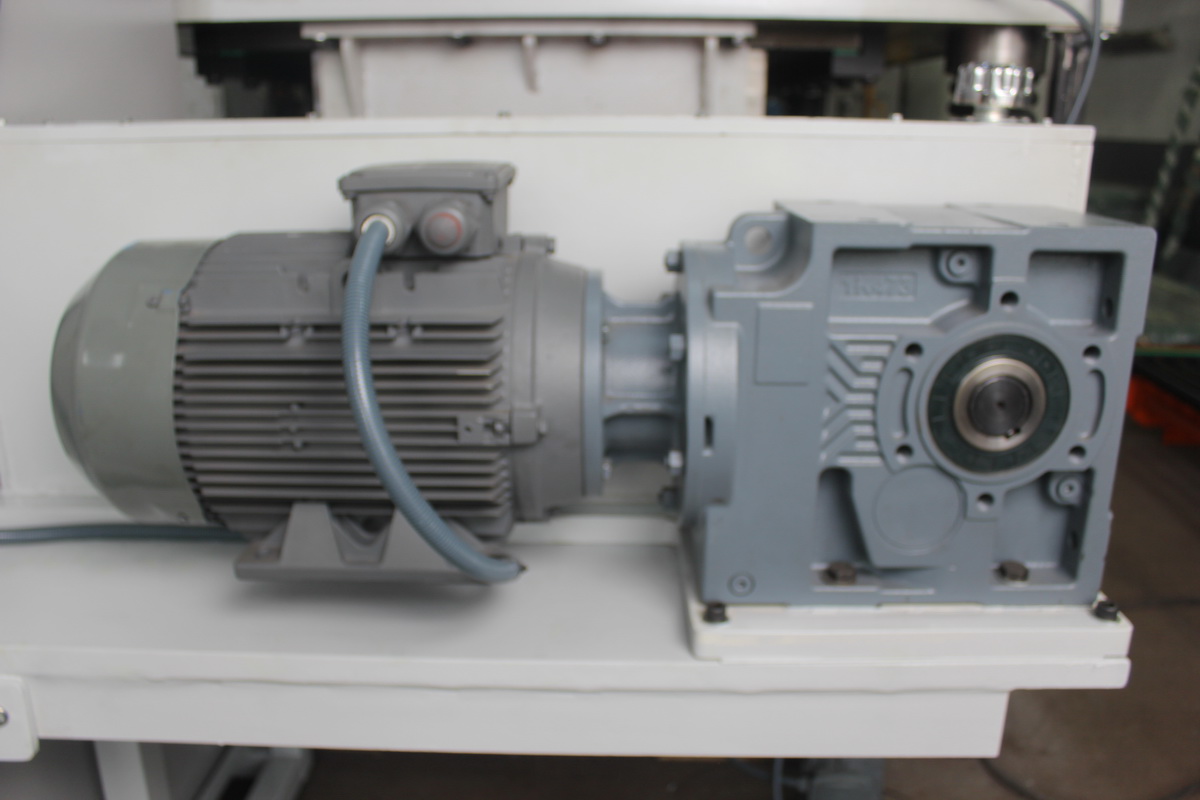

Metal Sheet Leveling Machine

FAQs

- What industries benefit from metal sheet leveling machines? Metal sheet leveling machines are beneficial in industries such as automotive, aerospace, construction, and manufacturing, where flat and precise metal sheets are required.

- Can a metal sheet leveling machine handle different types of metals? Yes, metal sheet leveling machines are designed to handle various materials, including steel, aluminum, and stainless steel.

- How often should a metal sheet leveling machine be maintained? Regular maintenance is recommended to keep the machine in optimal condition. Follow the manufacturer’s guidelines for maintenance schedules and procedures.

- What is the role of coil handling capabilities in a metal sheet leveling machine? Coil handling capabilities allow for efficient processing of coiled materials, reducing downtime during coil changes and enhancing productivity.

- Is speed an important factor in metal sheet leveling machines? Yes, speed is crucial for maximizing productivity and shortening production cycles. Look for machines that offer high processing speeds without compromising accuracy.

- Can metal sheet leveling machines be integrated with existing production systems? Yes, it’s important to choose a machine that seamlessly integrates with your existing systems, such as feeders, cut-to-length machines, or automation systems, to optimize workflow.

- What are the safety features to look for in a metal sheet leveling machine? Important safety features include emergency stop buttons, safety interlocks, protective guards, and advanced systems like laser scanners or light curtains for operator protection.

- How do I evaluate the return on investment for a metal sheet leveling machine? Consider factors such as increased productivity, reduced material waste, and improved product quality over time. A higher initial investment may be justified by long-term value and ROI.

- Can a metal sheet leveling machine be customized to specific requirements? Yes, customization options allow for adjusting leveling parameters, incorporating additional sensors, or integrating specialized software to align with specific production needs.

- What kind of customer support and training should I expect from the manufacturer? Look for manufacturers that offer comprehensive training programs for machine operation, maintenance, and troubleshooting, as well as responsive technical support.

Please show your support and appreciation by liking this prompt if you have found it truly helpful.

Leave A Comment