Dive into the fascinating journey of industrial machinery from the early stages of conceptualization to the final, functioning product. Explore how innovation, engineering prowess, and precision coalesce in the industrial machinery design process.

İçindekiler Tablosu

Stepping into the world of industrial machinery design is like entering a labyrinth of ingenuity, innovation, and sheer mechanical marvel. From towering cranes to minute circuit boards, every piece of machinery around us is the culmination of meticulous planning and skilled execution. But have you ever wondered about the journey these machines take from a simple concept to an actual creation? Let’s delve into the intricate and riveting process of industrial machinery design.

The Crucial Role of Industrial Design

At its core, industrial design is a symbiosis of art, science, and technology. It’s where aesthetics meet functionality, and creativity dances with practicality. With its roots dating back to the Industrial Revolution, the field has evolved from drafting simple machine components to designing complex, high-tech machinery systems. Today, industrial design plays a pivotal role in boosting economic growth, fostering innovation, and enhancing user experience.

Understanding the Concept Phase

The journey from concept to creation kicks off with a lightbulb moment – the inception of a novel idea or the identification of a need. The concept phase is where potential solutions are brainstormed, sketching out the machinery’s basic structure, function, and potential use-cases. It’s a sandbox for innovators where any idea, no matter how outlandish, has the potential to transform into a groundbreaking machinery design.

Drafting the Preliminary Design

Once the concept crystallizes, it’s time to translate these abstract ideas into concrete plans. The preliminary design phase involves drafting initial design specifications, outlining the machinery’s size, shape, functionality, and more. Designers often employ tools like CAD software for 3D modeling, lending a semblance of tangibility to their concepts.

Detailed Design and Analysis

The detailed design phase is where the rubber meets the road. At this stage, every component of the machinery is meticulously designed, keeping in mind its performance parameters, material compatibility, manufacturing processes, and costs. Simultaneously, an extensive analysis is conducted to test the design’s viability, involving strength calculations, simulations, and risk assessments.

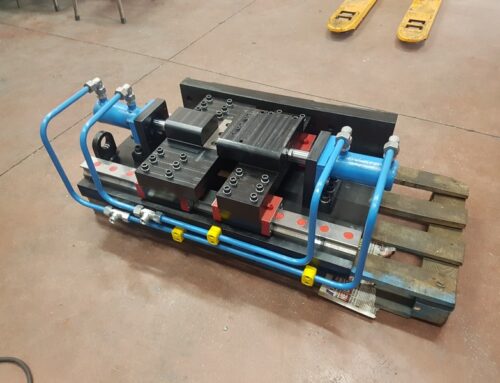

From Concept to Creation: The Importance of Prototyping

Prototyping is a crucial milestone in the industrial machinery design process. It’s the bridge between the theoretical design and the tangible product, allowing designers to test, refine, and perfect their creations before mass production. Rapid prototyping technologies like 3D printing have revolutionized this phase, enabling designers to transform their digital designs into physical models swiftly and affordably.

Material Selection in Industrial Machinery Design

The material selection process can make or break a machinery design. The choice of materials directly impacts the machinery’s performance, lifespan, and manufacturing costs. Hence, designers must carefully consider factors like the material’s strength, durability, cost, and compliance with environmental and safety regulations.

Industrial Design Software: The Technological Backbone

Industrial design software forms the technological backbone of the machinery design process. Tools like AutoCAD, SolidWorks, and CATIA offer advanced features for 3D modeling, simulation, and analysis, enabling designers to bring their concepts to life with unparalleled precision and efficiency.

Testing and Validation: Ensuring Functionality and Safety

Testing and validation serve as the gatekeepers to the manufacturing stage. This process involves rigorous testing of the design under real-world conditions to validate its functionality, safety, and compliance with industry standards and regulations. Any deficiencies detected are looped back into the design process for necessary revisions.

Final Design: Perfecting the Blueprint

Once the design passes the testing phase, it’s time to fine-tune the blueprint. The final design is a comprehensive plan that details every aspect of the machinery, from its components and assembly instructions to its maintenance guidelines and safety precautions. It serves as the cornerstone for the manufacturing process.

Manufacturing and Assembly

Transforming the final design into a fully operational machine is no mean feat. The manufacturing process involves various techniques, from traditional methods like casting and welding to advanced technologies like CNC machining and additive manufacturing. The assembly process then brings together the manufactured components to form the completed machine.

Quality Control in the Industrial Machinery Design Process

Quality control ensures that the finished product adheres to the design specifications and meets the requisite performance and safety standards. Through methods like visual inspection, performance testing, and failure analysis, any anomalies are detected and corrected before the product reaches the end-user.

Packaging and Delivery

Once the machinery clears the quality check, it’s packaged securely for transportation. The delivery process then ensures that the machinery reaches its destination safely and timely, marking the final step in the journey from concept to creation.

Lifecycle Management: Ensuring Longevity

The journey of industrial machinery doesn’t end with its creation. Lifecycle management ensures that the machinery remains operational and efficient throughout its lifespan through regular maintenance, timely upgrades, and eventual disposal or recycling.

The Impact of Sustainable Design Principles

In an era of climate change and dwindling resources, sustainable design principles have become integral to the industrial machinery design process. Incorporating sustainability can lead to energy-efficient machinery, reduced waste, and cost savings, striking a balance between economic growth and environmental conservation.

Innovation in Industrial Machinery Design

Innovation is the lifeblood of the industrial machinery design process. From AI-powered design tools to smart, IoT-enabled machinery, the field is constantly evolving, pushing the boundaries of what’s possible and setting new benchmarks for efficiency, safety, and sustainability.

Navigating the Challenges in Industrial Machinery Design

Despite its vast potential, the industrial machinery design process is fraught with challenges, including budget constraints, regulatory hurdles, and evolving consumer demands. Navigating these challenges requires a blend of technical expertise, creative problem-solving, and strategic planning.

The Role of Government Regulations in Design

Government regulations serve as a guiding framework for the industrial machinery design process. They establish minimum standards for safety, environmental compliance, and fair trade practices, ensuring that the machinery is safe for use, eco-friendly, and competitively priced.

The Future of Industrial Machinery Design

The future of industrial machinery design promises a fusion of cutting-edge technologies, sustainability, and human-centric design principles. Advances in AI, machine learning, and additive manufacturing, coupled with a renewed focus on sustainable and inclusive design, are set to redefine the landscape of industrial machinery design.

Conclusion: From Concept to Creation and Beyond

From the initial concept to the final creation and beyond, the journey of industrial machinery design is a testament to human ingenuity and technological progress. As we stand at the precipice of a new era in industrial design, the journey promises to be even more exciting, innovative, and transformative.

Frequently Asked Questions (FAQs)

- What is the first step in the industrial machinery design process? The first step is the concept phase, where ideas are brainstormed and potential solutions are outlined.

- How important is prototyping in industrial machinery design? Prototyping is crucial as it allows designers to test, refine, and perfect their designs before mass production.

- What role does software play in industrial machinery design? Software like CAD tools is indispensable for tasks like 3D modeling, simulation, and analysis, enhancing precision and efficiency in design.

- Why is quality control important in the industrial machinery design process? Quality control ensures that the finished product adheres to the design specifications and meets performance and safety standards.

- What are some challenges faced in industrial machinery design? Challenges include budget constraints, regulatory hurdles, and evolving consumer demands.

- How is sustainability integrated into industrial machinery design? Sustainable design principles can lead to energy-efficient machinery, reduced waste, and cost savings, balancing economic growth and environmental conservation.

Leave A Comment